-40%

Semi-Auto Metal Stamp Sheet Embosser 5mm Wheel Label Stamping Printer Machine US

$ 128.31

- Description

- Size Guide

Description

Store categorySign Up Now !

You may also like

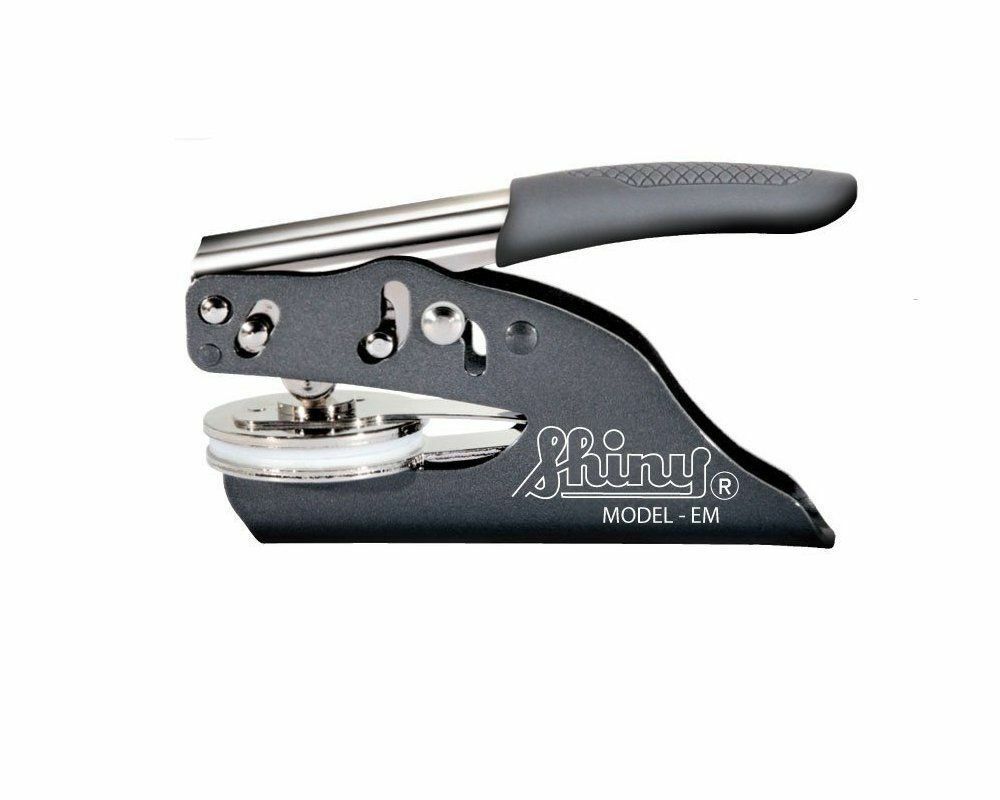

Semi-Auto Metal Stamp Sheet Embosser 5mm Wheel Label Stamping Printer Machine US

Product Description

Semi-Auto Metal Stamp Sheet Embosser 5mm Wheel Label Stamping Printer Machine US

Font size

height 5mm, width 2.5mm

Embossing Tool

Embosser

Modified Item

No

Custom Bundle

No

Material

Aluminum Alloy

Print content

English letters, Arabic numerals, simple symbols

Print speed

2-4 characters / 10 seconds

Type

Embosser Machine

MPN

Does Not Apply

Model

YK-A01

Embossing Supply

Die steel

Die Type

Embossing/Debossing Dies

Coloring Supply Type

Paint

Foil Machine Type

Roll Press

Type wheel model

5mm

Size

2*28.5*27cm/12.59*11.22*10.63inch

Marking area

18*13.5cm/7*5.3inch

Character wheel material

chrome steel (12CrMo)

Brand

Unbranded

P

roduct description:

Purpose: To imprint changing parameters on metal nameplates with a thickness of <1 mm: such as product model, date, batch number, serial number, etc.

technical parameter:

Name: Semi-automatic nameplate coding machine

Type wheel model:

5mm

Size: 32*28.5*27cm/12.59*11.22*10.63inch

Marking area: 18*13.5cm/7*5.3inch

Print content: (40PCS) letters, numbers, simple symbols

【

English letters: A B C D E F G H I J K L M N 0 P Q R S T U V W X Y Z, Arabic numerals: 1 2 3 4 5 6 7 8 9 0 simple symbols ·×/一

】

Font size: height 5mm, width 2.5mm

Font distance can be adjusted equidistantly

Character wheel material: chrome steel (12CrMo)

Typing speed: 2-4 characters/10 seconds

Full circle positioning error of code plate:

±0.10 mm

Application: Used for marking all kinds of aluminum, copper, stainless steel, alloy, plastic and other nameplates on mechanical equipment, electromechanics, water pumps, valves, automobiles and motorcycles, and electrical appliances

working principle:

※ The alloy steel letter plate after high-frequency quenching heat treatment is under the action of external force (tapping the rubber handle by hand), and then generates a certain impact force to engrave characters or numbers with a certain depth (0.1~0.3mm deep) on the nameplate;

※ The heat-treated steel letter plate can be rotated to the required characters or numbers, and the typeface can be easily replaced;

※ The marking position and line spacing are steplessly adjusted by a special mechanical mechanism;

※ The word spacing can be adjusted by the small handwheel;

※ Different character heights can be realized by changing the dial;

※Nameplates of various shapes of appearance

<200×130mm

can be clamped and printed.

Instructions for use:

A. How to place the signs:

Place the nameplate on the upper left corner of the work surface, use a clamp and a magnet to lean against the nameplate to ensure that the nameplate will not loosen.

B. Loading and unloading of letter wheel:

First, unscrew the lock nut counterclockwise by hand (or use an inner hexagon wrench to remove the pressure plate bolt), select a suitable character wheel, and install the letter wheel on the front side (fasten the pressure plate and tighten the two bolts), tighten the nut, and align the pointer .

C. Printing and starting position adjustment:

Place the nameplate workbench, loosen the bolts behind the rubber head, remove the clutch handle and hook it, and at the same time rotate the row spacing handwheel and the table moving handwheel, so that the characters on the letter wheel are aligned with the position directly above the print frame (can be compared Scale) Use the adjustable locking handle to lightly lock the row spacing carriage, loosen the clutch handle, press the feed handle, and at the same time adjust the proper word spacing with the lower right hand wheel of the machine to adjust, tap the rubber head with your palm, and press it again The feed handle operates with the same action to achieve continuous printing.

Daily maintenance:

1.

The machine should be kept dry and clean to avoid rusting of internal parts, and proper amount of lubricant can be added to the relative sliding surface regularly.

2.

It should be avoided that the rotary character wheel is directly printed on the work surface, causing unevenness on the table surface and affecting the printing effect. The character wheel should be removed and stored if it is not used for a long time.

3.

When adjusting the printing start position, be sure to loosen the clutch handle. Forcibly twisting the turntable to move the handwheel quickly will damage the transmission belt and make the word pitch feed inaccurate or malfunction.

Products include:

1* Semi-Automatic Sheet Embosser

1*5mm word wheel

1*Fixed fixture

Payment

Delivery details

Feedback

Return policy

Customer Service

Payment

We accept PayPal payment only

Payment must be received within 7 days after order is made.

Fees such as import duties, taxes are not included in the item price or shipping costs. These charges are the buyer's responsibility.

Delivery details

Shipping

from Germany warehouse to Europe buyers!

3-7 days: GERMANY

5-10days: Other countries

Shipping from our US warehouse to United States, which is more faster than from aboard.

2-9 working days to: USA

4-10 working days to: Canada

Feedback

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

Return policy

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

Customer Service

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

Feedback

On Jul-07-21 at 23:33:05 PDT, seller added the following information: